DIYIR Assembly Instructions

Prerequisites

You will require at least the following before starting:

- An official DIYIR kit

- Soldering iron & iron cleaner(sponge or similar). As most of the components are relatively small, most soldering irons will do & high powered professional soldering irons are not required.

- Solder with integrated flux

- Tin the tip of the soldering iron before starting.

- Experience with soldering or instruction on how to solder. Do not attempt this project, until you have appropriate skills or are under direct supervision.

- A desk, table or bench on which to assemble the module. To protect the surface cover with a suiteable material.

- Online access to these instructions or a printout to follow.

- A power socket to connect your soldering Iron (unless you are using a battery powerd iron).

- If you are soldering as part of a class or course, follow the instructions of your instructor.

- Having a Multimeter or DMM to verify resistor values is optional. (resistor values can also be visually verified from the colour bands without the need for a DMM).

- If you are unsure of which component is which refer to the diagram provided or contact us to confirm. If you insert the wrong component you may damage the module and/or your MCU.

Precautions

Soldering irons can reach very high temperatures and can burn your skin, damage property or lead to a fire if handled incorrectly. Where possible wear protective glasses and ensure your area is properly ventilated and well lighted.

General approach

We suggest to populate the PCB in the order of smaller/lower profile components first, gradually progressing to the larger/higher profile components. If you are unsure as to the best approach to soldering a particular component, please refer to the numerous tutorials available on Youtube and online. Please read all of the instructions before starting and read each step in full again before commencing that step.

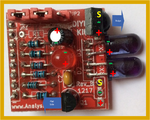

Component identification

Step 1 - Resistors

Solder the 6 resistors to the PCB in the following order - R2, R3, R4, R5, R6, R7. R1 is not included in the kit and is only relevant for advanced users who want to increase the IR power even more. This should not be required in 99%+ of cases. Contact us directly before you attempt this. Resisistors can be soldered in any orientation, but it looks nicer if they are inserted in such a manner that all the colour markings line up the same way.

Step 2 - Transistor

Solder Q1 the 2N4401 transistor. the orientation is marked on the white silkscreen. There is a flat edge which should aligned with the flat side indicated on the PCB.

Step 3 - Capacitors

First solder C2 (the smaller 100nF capacitor), followed by C1 the larger 10uF electrolutic capacitor. C2 can be inserted in any orientation, but C1 one is polariezed and must be inserted in the correct orientation. For C1, you will see a + & - sign on the underside of the PCB. The electrolytic capacitor C1, has a white wertical band down one side, which is the -ve side. Connect this side to the pin marked -ve.

Step 4 - IR LEDs

The 2 IR leds are connected into position D2 & D3. The orientation is relevant for LEDs and as mentioned elsewhere the longer lead is the +ve side of the LED, the shorter lead being the -ve side. On the underside of the PCB you will see the +ve pin marked for D2 and you should insert the first IR LED with the longer lead into this pin. (The longer lead will be on the side nearest to transistor Q1. The second IR LED is then soldered into Position D3 with the same orientation for the longer lead. Similarly, the longer lead will be on the side nearest Q1. Either IR LED can be inserted into D2 or D3.

Step 5 - Red LED

The red led is inserted into position D1. The orientation is relevant for LEDs and as mentioned elsewhere the longer lead is the +ve side of the LED, the shorter lead being the -ve side. On the underside of the PCB you will see the -ve pin marked for D1 and you should insert the red LED with the shorter lead into this pin. (The longer lead will be on the side nearest to transistor Q1.

Step 6 - IR Receiver

Install the IR receiver intothe position IRrx1 or IRrx2 with the bulgedge facing away from the PCB. It is important to get this orientation correct.

Step 7 - Headers

Install header P1 either above or below the PCB. Below is good for use with a breadboard, while above is good for use with female jumper wires. You can alternatively just solder wires directly to the pins, if you prefer.

Install 5 pin header into position JP1 & JP2.

Install the 2 jumpers into JP1 and either the 5V or 3V3 slot on JP2 to suit your requirements.

Step 8 Pre-flight checks

Before appying power or connecting to your MCU, double-check that all components are installed correctly and that the solder joints appear to be good. Correct errors if any are found.

If you have a DMM available you can carry out the following optional tests: Test 1 - Measure the resistance between + & - on P1 and verifyit is not s short(reading <5 ohms) Test 2 - Measure the resistance between S and + on the IR receiver. It should measure between 30K and 40K ohms. You can use the unused receiver position to make the measurement. Test 3 - Measure the resistance across all resistors and verify they are approximately correct, as follows:XXXXXXX. Test 4 - With the DMM in diode mode, measure the voltage across the Ir LEDS individually. each one should read approximately xxVolts. Test 5 - With the DMM in diode mode, measure the voltage across both IR LEDs. The voltage should read approximately xxxxVolts. Test 6 - With the DMM in diode mode, measure the voltage across the RED LED. The voltage should read approximately xxxxVolts. This is lower than the expected 1.8Volts for a red LED because the tranistor is in parallel and we are actually measuring the base emitter voltage.